In an era of sluggish mattress sales, shifting consumer expectations and intensifying global competition, coil and innerspring manufacturers are refining their strategies to stay competitive, generate greater demand and redefine what they bring to the bedding industry.

Innerspring Manufacturing Faces Global Competition and Volatility

Dominik Meyer, CEO of AGRO Group’s A&S Innersprings in Windsor, Connecticut, describes the current period as “the biggest change process I’ve seen in my 20 years in the coiling industry.” With market pressures reshaping everything from labor to design, he expects the pace of transformation “to continue for the next 10 to 15 years.” Meyer believes that success will hinge on cost-effective production, sustainable practices and sharper product differentiation for coil manufacturers to survive and thrive amid global volatility.

That sense of disruption is echoed across global markets. Ken Tsai of Guangzhou Lianrou Machinery & Equipment in Guangzhou, China, points to the homogenization of spring designs as a key pressure point. “Low technological thresholds lead to fierce competition,” he says. Even so, he sees opportunity in developing new products and tapping into “hidden demands” that aren’t being met by conventional offerings.

Darren Marcangelo, chief commercial officer for Spinks in Leeds, England, views the slowdown in mattress sales through another lens: overcapacity. “Global mattress demand has slowed, leading to some overcapacity in coil manufacturing,” he explains. “We don’t expect full recovery until 2027, but consolidation in the mattress industry could streamline and strengthen the coil market” — a shift that may streamline operations and leave the market more resilient.

Tapping New Demand: Specialty Coils and Sustainable Innovation

Even with slower mattress sales, the appetite for innersprings appears to be gradually rising. Coil makers are finding traction in specialty segments, sustainable designs and performance enhancements that help mattress manufacturers stand out.

Meyer points to AGRO’s specialty coil category, which has grown by more than 10% despite what he calls “restrained purchasing behavior among end consumers.” He’s realistic that specialty coils “will never represent the big volumes” but stresses that they open doors to higher-margin opportunities.

At Lianrou, the emphasis is on health and sustainability. Tsai says the company is developing glueless and detachable pocketed spring units that cater to healthy bedding trends while making recycling easier. He expects pocketed springs to gain market share as Bonnell systems continue to lose relevance in medium- to high-end products.

In the United States, UTC, which has North American headquarters in Danville, Virginia, is seeing a shift of momentum to perimeter-plus units, which Robert Loy, director of sales, says are overtaking demand for foam encasement. “The market seems to be rediscovering the charm of a well-built spring,” he says.

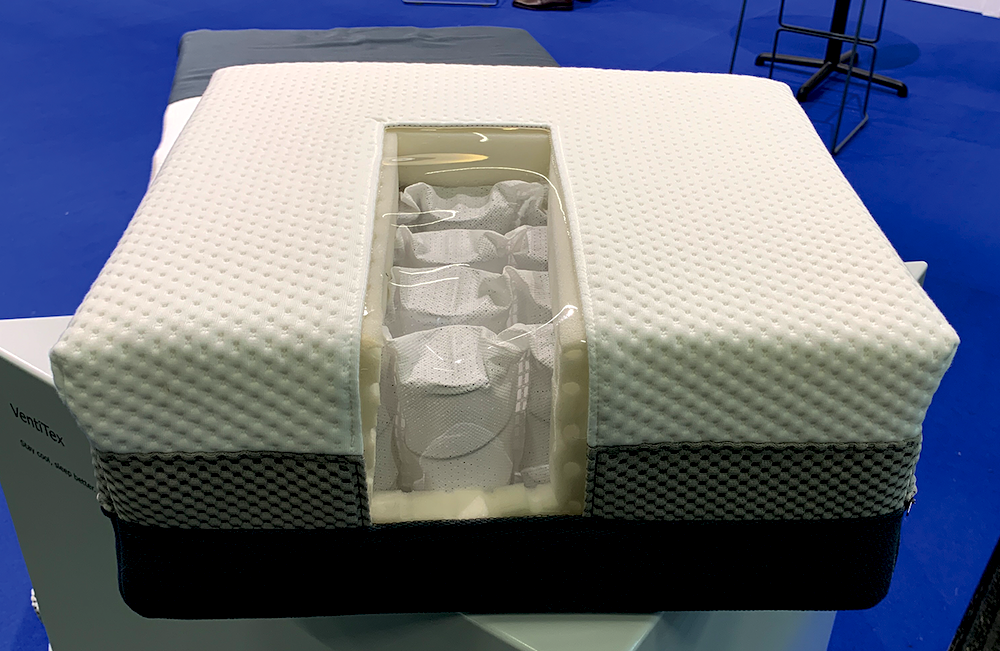

At Spinks, Marcangelo reports “a significant increase in demand” for premium microcoils, particularly those featuring 3D fabric options. He says the company is also catering to “customers at the mid- to high-end of the market … looking for a point of difference” in the marketplace.

Cost Pressures: Navigating Raw Material Volatility and Trade Tariffs

In addition to inconsistent demand and lackluster mattress sales, raw material volatility, rising labor costs, global tariffs and overcapacity pose significant obstacles to growth for coil producers.

“We all are prepared for larger volumes, and this underutilization comes with some challenges,” Meyer says. Idle machines, unused capacities and retaining a skilled workforce can strain a company’s profitability and efficiency, complicate supply chain planning and put producers at a competitive disadvantage.

At Lianrou, Tsai singles out the sameness of product design as the industry’s greatest challenge: “When every manufacturer is producing similar innersprings, the one who can control costs, make the best quality and build the best brand will win the market.”

Loy points to materials and trade policy as constant hurdles. “Raw material costs are like a roller coaster,” he says, noting that bulk buying and vertical integration help UTC stay ahead of the curve. “Tariffs have reshaped the playing field, and only those with efficient, integrated operations can stay competitive,” he says.

To offset rising labor costs and taxes in the United Kingdom and U.S. tariffs, Spinks is shifting more microcoil production to its facilities in North Carolina and Wisconsin, which are part of Spinks’ HS2 joint venture with Hickory, North Carolina-based Hickory Springs Manufacturing Co. Marcangelo adds that the company is protecting its innovations with patents and roll packing its products to making them accessible to customers globally.

GenE Goes Glue Free

Dallas-based Texas Pocket Springs’ GenE pocketed coil assembly uses a double-seam thermal welding process instead of glue, forging pliable, welded bonds that won’t break down in extreme heat or cold.

CEO Martin Wolfson says the fully recyclable unit “makes pocket coils stronger, lighter and more comfortable,” preserving the supple feel manufacturers and consumers expect.

Future-Proofing Innersprings: Reinvestment in Automation and Smart Design

Across the industry, reinvestment in equipment, automation, sustainability and adaptability is shaping the next generation of innersprings.

While machinery once lasted decades, Meyer says today’s producers must continuously reinvest in new and more efficient equipment to remain competitive. “Now after only a few years, you need to invest in new or additional machines to produce all-new coil designs,” he says. For AGRO, that means prioritizing flexibility, automation and modular systems that can be upgraded easily to minimize downtime. Its latest designs integrate reinforced edges, larger springs, new materials and higher coil counts engineered for greater compatibility with modern automated mattress lines.

At Lianrou, innovation centers on developing “unmanned, intelligent, flexible and customized” production systems. According to Tsai, the company is building high-efficiency machines that use sensors and program controls to ensure precise, consistent production, minimize raw material waste and reduce the proportion of labor in production. “The amount of steel wire used can be lessened through reducing the number of spring coils or increasing the pitch of the steel wire diameter,” helping reduce materials while increasing product sustainability, he says.

UTC is focusing on coil designs and machinery that are customizable, scalable and engineered to keep pace with the demands of modern mattress manufacturing. “If you are not drawing your own wire and producing your own nonwovens, it will be very hard to stay competitive,” Loy says. He adds that UTC is developing “smarter” springs with multiple geometries and wire gauges in the same unit, and machines capable of producing more than 200 coils per minute.

Spinks commits to substantial annual investments in its manufacturing facilities in the United Kingdom and the United States to spur new development. Marcangelo says integrating automation, artificial intelligence and robotics helps reduce labor costs — but insists that “skilled electrical and mechanical engineers and programmers will remain essential to the success of the coil factories of the future.” According to Marcangelo, the company’s machines now produce more than 1,000 coils per minute, while its “Springs Anywhere” software creates exclusive designs with firmer edges, custom and gradual phased zoning for soft to firm comfort profiles. The company is also experimenting with “intelligent fabrics” designed to expand the comfort and performance envelope of coil systems.

New Spins on Coils

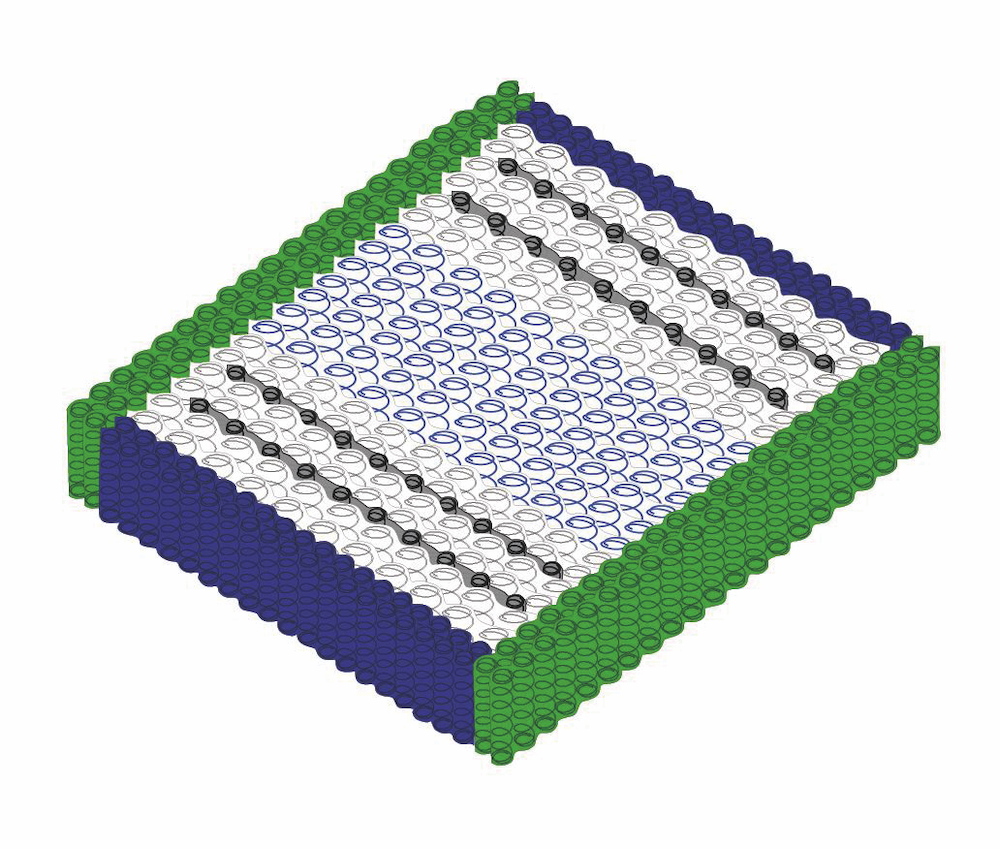

In today’s stagnant marketplace, these coil producers are rolling out new constructions to help jump-start sales and increase demand for their products in today’s volatile marketplace.

*UTC: The company says it has several new coil and innerspring constructions in development which Robert Loy, director of sales, says remain “top secret for now.”

| A&S Innersprings /AGRO Group | Guangzhou Lianrou Machinery | Spinks |

|---|---|---|

| Cottonflex: A spring core made from breathable, tear-resistant cotton and thermally treated springs for dimensional stability and a comfortable sleep experience. | Glueless pocket spring units: These pocket springs are connected by ultrasonic welding, that is much longer, stronger and more environmentally friendly than glue dots. | Microlution: This two-stage approach combines two coils working together to provide initial comfort with secondary support — all in a single layer. |

| Jumboflex SB: A 25-centimeter-tall spring core with tightly bonded sides and reinforced material that provides stability to large-area mattresses — designed exclusively for the North and South American markets. | Detachable sewing pocket spring units: A sustainable mix of sewing and ultrasonic technology makes end-of-life recycling easier. With removable stitches, the pocketed springs can be separated into steel and nonwoven fabric. | Quadrolution: A customizable glueless core that positions Response coils between recyclable springs to create a secondary support system. |

| SmartPocket GL: A recyclable, two-component, glueless minipocketed spring core with high dimensional accuracy and 50-millimeter grid spacing for edge-to-edge solutions. | Pillow pocketed springs: Its lightweight design is more eco-friendly than foam with better ventilation than latex, according to the company. It’s made with thinner wire, nonwoven fabric and an adjustable innerspring that can be configured in different pillow shapes and sizes. | Micro Copper: An antimicrobial, antifungal nonwoven infused with copper used in medical applications, — available for most of Spinks’ product range. |

| SquareFlex: GL: A 2 ½-centimeter glueless minipocketed spring system offering flexibility ideal for toppers and multilayer mattress setups. | Micro Trio: A three-in-one coil that offers plush comfort before the second and third coil provides greater support. | |

| Full-height cores: Elevates performance and comfort — launching later this year. |

Read more industry news and features at BedTimesMagazine.com.