I feel the need, the need for speed.” That iconic line from the movie “Top Gun” summarizes the state of bedding machinery. And while creating faster machinery is essential in a competitive marketplace, suppliers are also innovating ways to reduce labor and be more accurate and sustainable.

Innovating for Less Packaging

Reducing packaging volume has been a key focus for machinery suppliers in recent years. Less packaging allows more units per shipping container, leading to lower emissions and decreased shipping costs.

“Let’s say — in the last 10 years — we know how to smash the product and get it to be as small as possible,” says Mark DeCoteau, director of U.S. operations for Verona, Italy-based Dolphinpack. “So, I don’t think that’s where things are going to go. It’s more about how we service the customers. How do we reduce their waste or reduce their cost in the amount of plastic they use? And also the amount of labor they use.”

Tackling Labor Challenges with Innovative Machinery

One of the biggest priorities in machinery today is labor reduction — particularly end-to-end automation that eliminates manual labor in traditionally overlooked areas.

Paul Block, president of sales at Gribetz, says this is a focus for the Sunrise, Florida-based company (formed after the purchase of Global Systems Group by ABM International earlier this year). “The mattress industry has been facing many challenges since Covid,” Block says. “We believe the single biggest challenge our customers face is centered on the availability of skilled labor, and it will require a new age of production machinery that can increase efficiency, reduce waste and simplify assembly.”

Mitch Nussbaum, marketing specialist at C3, a machinery supplier in Appleton, Wisconsin, echoes Block’s sentiments. “Labor remains a key pressure point for our customers, and it’s not going away. Over the next three to five years, we see machinery continuing to evolve through targeted automation — strategically placed systems that reduce reliance on manual labor without overcomplicating operations. Smart machinery will become more user-friendly, more connected and more scalable — supporting manufacturers who need flexibility without sacrificing performance.”

End-to-End Automation and Smart Machinery

Labor reduction goes hand in hand with automation. “With rising costs, tighter margins and fierce competition, manufacturers are looking to minimize waste, increase in-house capabilities and streamline operations,” says Dhruvin Patel, global sales manager at Bursa, Turkey-based Elektroteks.

C3’s End-of-Line Automation System, introduced in January, handles everything from case erection through palletizing. It provides manufacturers with a fully integrated end-of-line workflow that improves throughput and reduces manual handling. Its upcoming High Scale Automation for Hybrid Bed Construction, launching in September, is designed to handle complex assemblies like hybrid mattresses.

camera-based system to align adhesive paths.

Atlanta Attachment Co.’s most recent innovation isn’t a piece of equipment but controls. With its Gateway 2.0 launch, it integrated its proprietary serial bus control system with an industrial PC, allowing it to leverage the benefits of connectivity and peripherals of the PC ecosystem. Users can remotely (via server or the cloud) upload and download production schedules, unique recipes and parameters for beds, view production data, receive maintenance feedback from data and push settings out from a central location.

“Since you are connected to an industrial PC, you enable rapid integration of peripherals like barcode scanners, RFID scanners and printers,” says John Chamlee, vice president of business development at the Lawrenceville, Georgia-based supplier. “The power of the PC connection allows easy future integration of AI. We are allowing customers to quickly and cheaply update their 20-year-old machines to leverage this kind of connectivity. Since the system uses our serial bus control system as the machine I/O (input/output) backbone, we can do this without the need to throw out existing controls and wiring.”

According to Block, ABM’s core strengths are also in software development and servo controls. “Our mission is to design, build and manufacture a full line of highly automated, most cost effective mattress producing equipment in the industry,” Block says. “Many of these innovative machines were game changers for the world of mattress production and became staples of every mattress factory. These included various models of quilting machines, flanging machines, binding machines, label and repair machines, conveyor and material handling equipment, and many others.”

At Dolphinpack, the company has been upgrading its machines, including being able to seal plastic at a thinner gauge, thus reducing the plastic necessary to compress, fold and roll a mattress up to 65%, and automation tools like quality control, which uses cameras and artificial intelligence. “It helps standardize the process and minimize timing. If you’re running a factory five or six days a week, it becomes a huge advantage,” says Matteo Tagliaferri, global sales manager for Dolphinpack.

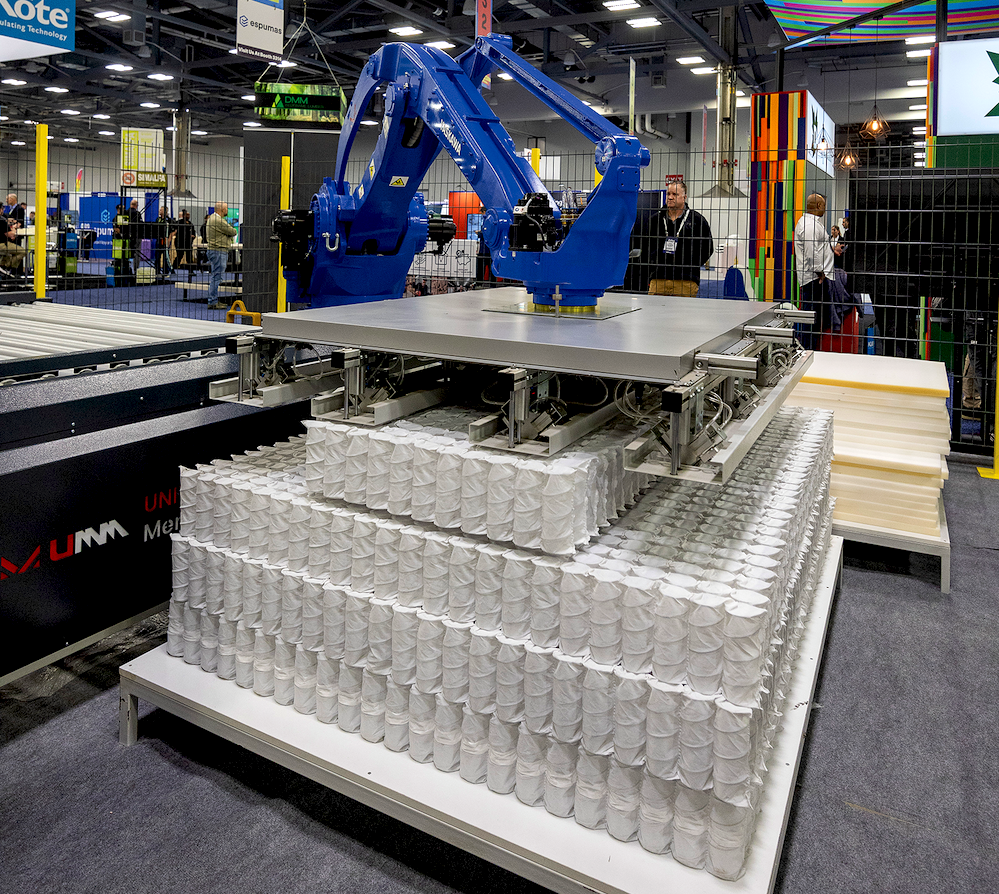

Michael Porter Jr., co-founder of United Mert Makina, headquartered in Delray Beach, Florida, says total automation isn’t realistic. “People have been trying to fully automate and reduce all human participation in mattress production. Based on the nature of the product, that will never work, especially for high-end mattresses,” he says. “UMM is working to develop machinery that incorporates automation to make mattress producers’ lives easier, but with machines that work long-term in the field.”

The Rise of Vision-Based Technology in Machinery

Vision systems — automated tools that mimic human sight — are becoming central to automation.

Earlier this year at Interzum Cologne in Cologne, Germany, C3 debuted an updated version of its Vision-Based Hot Melt Application, an intelligent gluing system that uses vision to detect each part and apply adhesive precisely, no recipes required. It adapts in real-time to part variation, improving speed, accuracy and reducing changeover time.

“This solution eliminates the need for traditional gluing recipes, using a camera-based system to locate and align adhesive paths based on real-time part geometry,” Nussbaum says. “It solves a common bottleneck in production — slowing down for changeovers or minor part differences. With this technology, manufacturers can continuously run different parts at high speed — up to one part every six seconds — without sacrificing precision or throughput.”

Elektroteks has also automated its production lines with RFID, vision systems and barcode integration. Now, with its FoamET and NEXUS systems, it has been able to apply the same level of automation to its foam handling business, Patel says.

The Next Frontier: AI-Powered Manufacturing

Beyond vision systems, AI is the next step in smart machinery.

“I think that machinery in general will begin to incorporate AI into their DNA and become more and more valuable to the user, especially in its ability to troubleshoot and offer solutions to the user,” AAC’s Chamlee says. “Certainly, AI will continue to push into areas of quality control and secondary processes. Things that are now processed outside of the production line and outside of the ‘machinery’ will become integral without the need of outside processes.”

That’s also true at Elektroteks. “Our goal is continuous innovation — enhancing speed, flexibility and integration based on customer needs and market demands,” Patel says. “With AI at the center, future systems will be smarter, more predictive and even more sustainable. We’re investing heavily in AI. Our upcoming AI Agent will help manage predictive maintenance, service schedules, batch production and more — all aimed at improving efficiency and reducing downtime.”

According to Patel, Elektroteks is also working toward fully connected, AI-driven facilities called “dark factories,” requiring minimal human intervention.

Block is optimistic about AI, too. “Gribetz utilizes all available technical tools in order to find ways to improve machine efficiency,” he says. “Artificial intelligence offers so many amazing new ways to approach machine design and support. We are extremely excited for the future.”

The Focus on Sustainable Machinery and Materials

Alongside speed and AI integration, sustainability is another top priority. For example, Dolphinpack introduced an improved version of Etesian machine named Smart Hybrid, which allows for packaging items in paper, rather than plastic. Such a shift reduces as much as 96% of the plastic used to compress, fold and roll mattresses, company officials say. Starting in 2022, they collaborated with major manufacturers to help them transition to paper packaging for mattresses and upholstery items. “In 2023, we ran six months’ worth of testing in our factory on our machines because we were the first ones to have implemented paper in the modeling,” Tagliaferri says.

Meanwhile, at C3, the company is working on packaging alternatives and systems longevity, “so customers can reduce waste while extending machine life,” Nussbaum says. One example is C3’s Topper Packaging System, updated in late 2023, a flexible packaging solution that allows customers to use stretch film or paper, depending on sustainability goals or cost preferences.

To optimize resource usage and cut waste, Elektroteks is leveraging AI through its Elek-AI platform. That, according to Patel, paired with its next-gen, batch-mode will be a powerful combination.

Sustainability is also a focus at Gribetz. “Gribetz machines are held to high standards of energy efficiency, waste reduction and use of durable, recyclable materials,” Block says. “Many current Gribetz machines use techniques for reducing scrap and saving our customers capital in this efficiency. We provide our customers with scrap removal and baling systems that completely automate the scrap removal process and eliminate nonvalue-added labor from the process.”

Customer-Centric Approach to Machinery

Although machines are getting faster and smarter, one aspect of automated machinery is timeless, and that’s customer service.

Dolphinpack highlights its global response. “Our customer support is fantastic,” DeCoteau says. “You sell the equipment, but it runs every day. We can respond globally. We have 1,200 pieces of equipment in the field on five continents.”

At Gribetz, the company is focused on the United States. “The goal of the new Gribetz company is to become the leading supplier of machinery to the mattress industry through innovations in design and unmatched customer service,” Block says. “Our industry needs a strong U.S.-based equipment company with manufacturing and service right here in the U.S. Our customers are giving us excellent feedback. We are listening and hear what they want from an equipment company.”

Next-Generation Innovations and Industry Predictions

As for what’s next for UMM, the company is keeping it under wraps for now, but teases a major equipment reveal at ISPA EXPO 2026, which will take place March 10-12 in Orlando, Florida. “It is something nobody else has right now and will open up major doors for mattress producers,” Porter says.

For Gribetz, Block says the new ownership is looking at many challenges facing mattress manufacturing and its engineering team is working on innovations that the company will introduce in the near future.

“We are working to improve many of the previous assets of Gribetz,” Block says. “Through continuous improvement, quality control and a strong engineering team, we have the ability to react to trends and move quickly. ABM International is a fourth-generation, family-owned and operated company that has been building quilting machines and automated sewing systems for nearly 80 years. This brings a fresh perspective and vision to how the current equipment can function with both minor updates and new designs. Neal Schwarzberger is an innovative owner who brings hands-on skills to this organization. He works tirelessly and his perspective is hyperfocused on the potential of machines and customer support.”

Emerging Trends in Mattress Manufacturing

While priorities vary by company, several trends stand out. Nussbaum notes growing demand for foam encasement for coil units, prompting C3 to develop automation that applies foam tubs directly in-line with coil production, eliminating steps. He also sees stronger demand for modular systems that support scalability and faster changeovers.

Chamlee says border aesthetics remain a cost-effective way for manufacturers to differentiate their products, noting an increased emphasis on new handle designs and decorative border schemes. In October 2024, Elektroteks acquired Cologne-based quilting machine manufacturer Mammut to expand capabilities, with Patel observing strong interest in border quilting lines and in cutting foam in-house to reduce reliance on suppliers.

Block predicts major changes in mattress production techniques. “I believe that our customers are going to see changes to the way they are serviced by machinery companies, or we will set the standard and pave the way for others to either follow or be left behind,” he says. “Our customers will always be looking for new developments in machinery and looking for pathways to reduce labor and improve efficiency. We expect to be leading those developments and helping our customers find the machinery of tomorrow.”